Preface

This post describes: How to repair a Toilet Silent Fill Valve. Basically that’s how to replace the rubber diaphragm within the valve.

Introduction

I recently heard my cistern overflowing. On investigation I decided to adjust the float level to stop it by reducing the height to which the water in the cistern rose when it filled. A few days later I heard the distinct sound of the cistern overflowing again. I then realised I needed to repair my Toilet Silent Fill Valve.

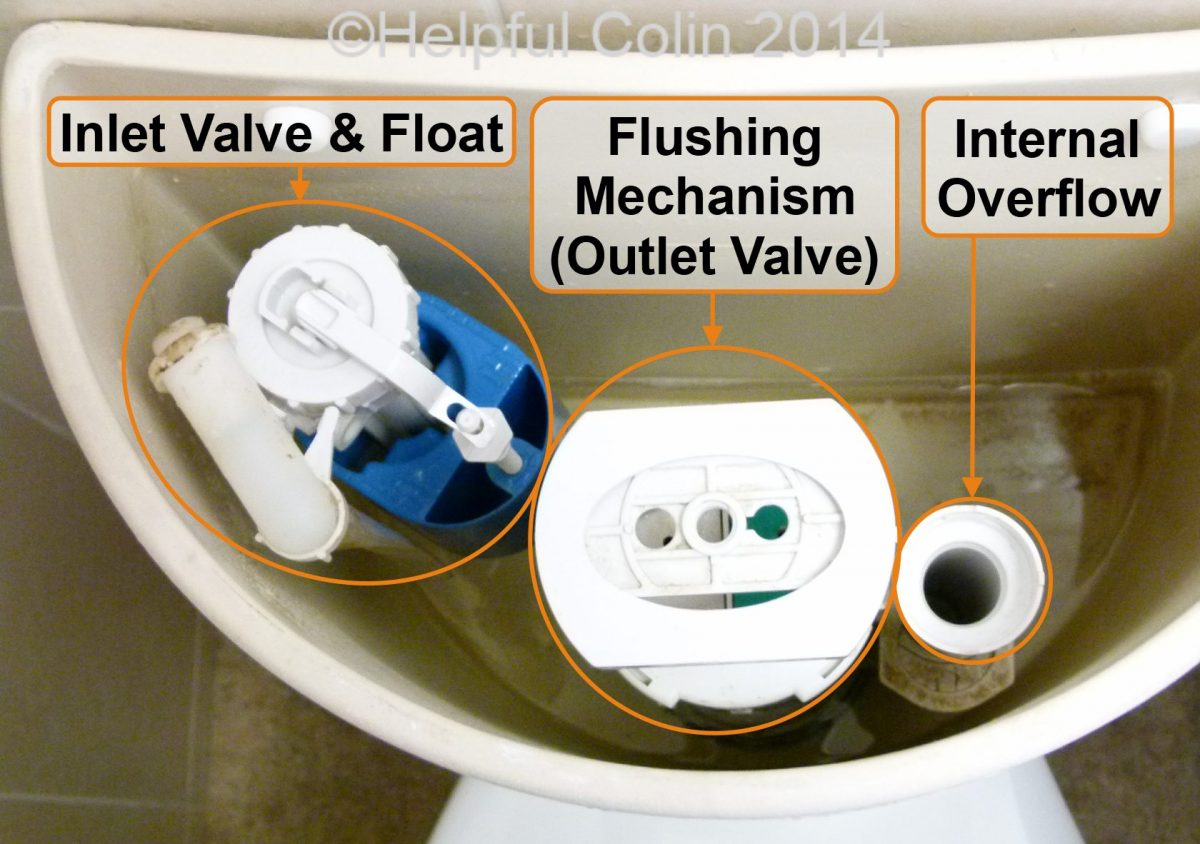

- Pic. 1. The internal parts of a dual flush toilet cistern.

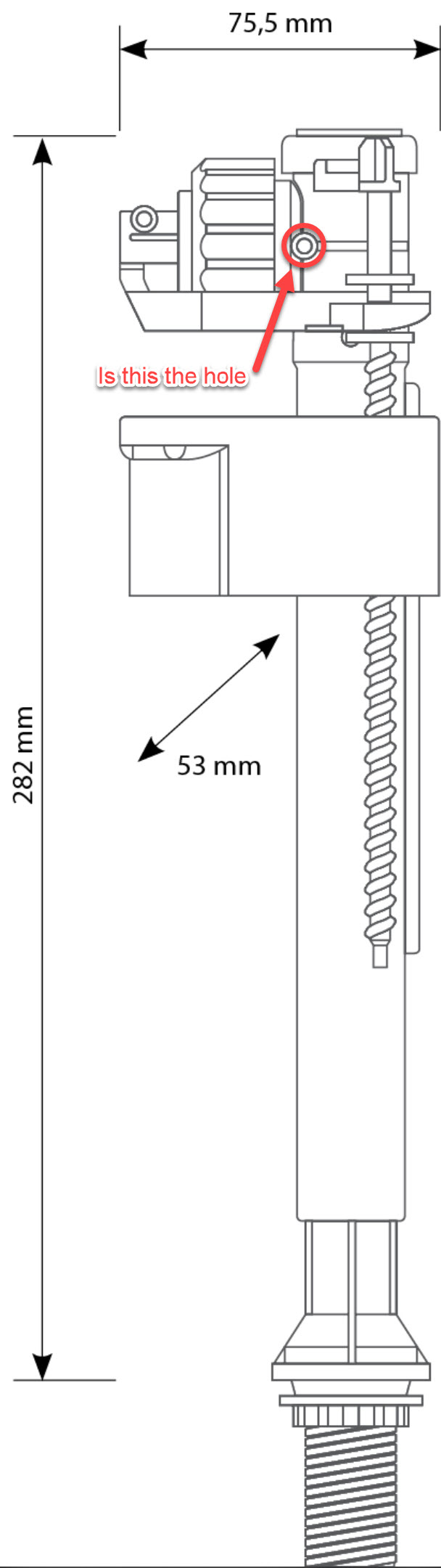

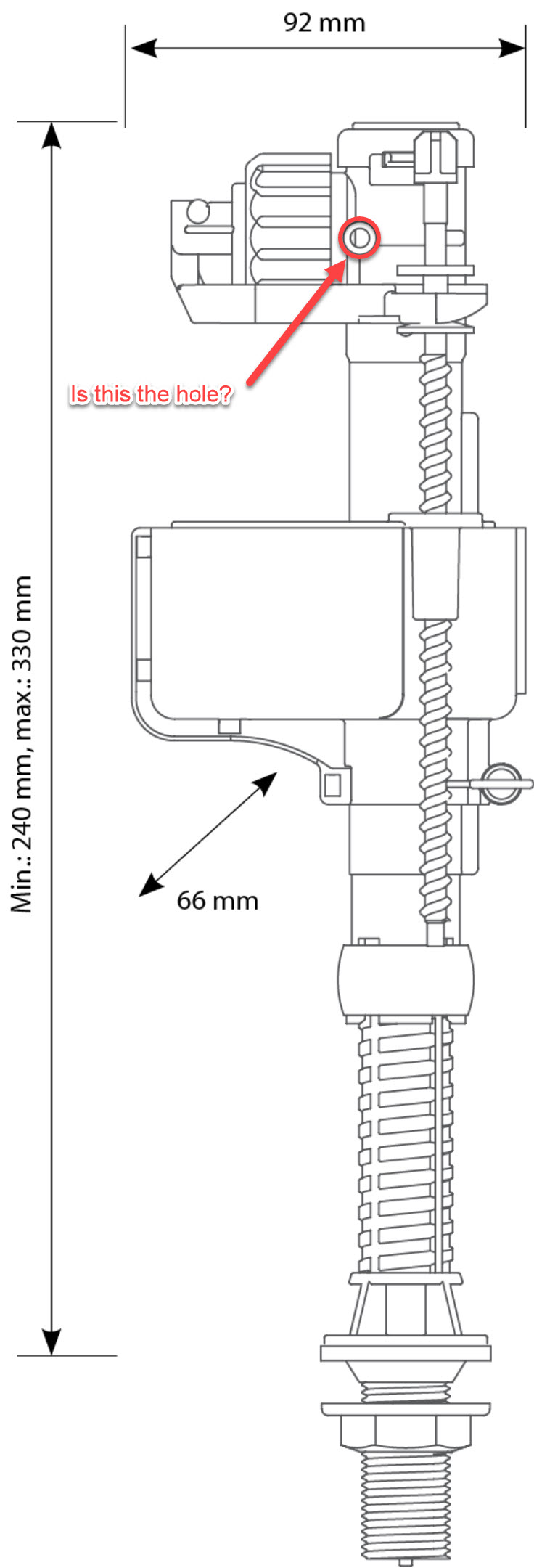

- Pic. 2. The silent Fill Valve and Float System with labels.

- Pic. 3. Here the Clamping Nut, Top Cover and Arm have been removed.

- Pic. 4a. Water Turned ON

- Pic. 4b. Water Turned OFF

- Pic. 5. Fill Valve with the Top Cover removed and the Diaphragm in place.

- Pic. 6. Fill Valve with the Top Cover removed and the Diaphragm removed.

- Pic. 7. A Damaged Diaphragm – holes show when it is stretched.

- Pic. 8. White and Red Pinned Diaphragms side by side.

- Pic. 9. Diaphragm

- Pic. 10. The Diaphragm in detail.

- Pic. 11. Top Cover Assembly with the Arm threaded through the Clamping Nut.

- Pic. 12. Top Cover Assembly with the Clamping Nut detached.

- Pic. 13. Valve with the Arm removed and the pinhole exposed.

- Pic. 14. The Arm (upside down).

- Pic. 15. The underside of the Top Cover of the new Twist Lock valve with a Red Pin diaphragm.

What Is The Valve Called?

In order to satisfy the requirements of Internet SEO (Search Engine Optimisation) the valve is referred to, in this article, specifically as a Toilet Silent Fill Valve or more generally Silent Fill Valve but its full title is a Silent Fill Toilet Cistern Inlet Valve since it is:

- A Valve.

- An Inlet Valve.

- A Cistern Inlet Valve.

- A Toilet Cistern Inlet Valve.

- A Silent Fill Toilet Cistern Inlet Valve.

Old & New Fill Valves Compared

Repairing a Toilet Silent Fill Valve used in a toilet is, in my opinion, easier to perform than one on a traditional ball valve (ball cock). Modern inlet valves take up the minimum of space with their small float, are made of plastic and can often be dismantled by strong hands without any spanners because their screw threads don’t jam with calcium and corrosion like brass ones. They are available in various formats. Some mount through a hole in the side of the cistern, and are a good replacement for old brass ones (which are usually mounted that way), while others stand on a tubular stalk inside the cistern which mounts through a hole in the bottom of the cistern.

When the fill pipe is attached at the bottom of the cistern the pipe can often be situated out of sight. Bathrooms look much nicer and cleaner when pipes are out of view.

It may be that a Replacement Fill Valve is required. If so take a look at my article “Replacing A Toilet Fill Valve”.

To find out how a Toilet Silent Fill Valve works see the addendum to this post entitled:

Why Is It Silent?

This type of inlet valve is referred to as silent because it is designed to fill the cistern quickly (mine takes about 30 seconds for a small flush and 45 seconds for a large flush) and without the sounds of rushing and splashing water within the cistern. The silence is mainly achieved by keeping the outlet of the inlet valve below the water level in the cistern.

Syphoning Back From Cistern To Supply

If the inlet valve outlet fed into the water through a solid round pipe it would be susceptible to becoming a syphon. This might occur under adverse conditions when the supply pressure is low, e.g. when the water supply to the house is turned off. Water could then syphon back into the supply pipes1. The water authorities are very keen to prevent syphoning back into the supply with any connected apparatus in case the water main gets contaminated by it. People in the same building could end up drinking the water siphoned back. In the past they would not have allowed any inlet valve outlet pipe to be immersed.

However by using a collapsible polyethylene pipe for the outlet (its like a narrow polyethylene bag with a hole in the bottom) siphoning can’t take place. The flexible polyethylene pipe doesn’t float up and lay on the water surface because it has a thin plastic rod inside it which keeps it pointing straight down. I think that if it did float on the surface water might spray in all directions within the cistern. Remember they don’t have watertight lids since air has to get in rapidly to replace the water when it is flushed out.

When the cistern is filling I can still hear water flowing in the house pipes, but only for a short period.

My Ideal Standard Toilet Silent Fill Valve was supplied with my Armitage Shanks toilet in 2007. It’s served me well needing very little float level adjustment and no replacement parts in the intervening period up to April 2014. I have now just replaced the diaphragm again in February 2019.

Accessing My Toilet Silent Fill Valve

To perform any operation inside the toilet cistern the lid must be removed. I have already posted an article describing how to do that on a modern push button toilet like my Armitage Shanks Ascania WC. You can read it here entitled ‘Dual Flush Toilet Cistern Lid Removal’. With older ceramic cisterns that are close coupled to the pan, or just above it, the lid usually just lifts off. I’m sure some plastic cisterns have some screws around the edge of the lid holding it on.

Cistern Overflows

My Internal Overflow

Pic. 1. The internal parts of a dual flush toilet cistern.

My cistern overflows internally through a pipe rising from the bottom of the cistern. (See adjacent image.) The output from this overflow pipe drains straight into the toilet pan at the point where the flushing water enters. The overflow pipe is integral with the flushing mechanism.

The height of the overflow can be adjusted. The top section is just a pipe with a screw thread moulded on it. It can be screwed in and out of the bottom section. So turning it clockwise lowers it and anticlockwise raises it.

Why it took a century to develop an internal overflow I don’t know. All the problems with external overflows disappear with an internal overflow.

The Problems With External Overflows

- Water pouring all over the paths outside and then freezing in winter in cold climates.

- Water pouring down the wall of a house where the overflow pipe is too short or doesn’t hang down or the wind blows the water back to the wall. Unattended this can seriously damage a wall causing damp, mortar erosion, mould and bad staining which then ruins the look of a property.

- Icicles hanging from overflow pipes which break off and injure people underneath in cold climates.

- Water in the overflow pipe freezing whilst overflowing in cold climates causing the overflowing water to back up and spill indoors.

- Toilets need to be near an outside wall or have a lengthy and maybe problematic overflow pipe run on the inside of the building.

- Cold air blowing into a clear overflow pipe from outside and passing across the top of the water in the cistern. This can chill the water in the cistern by evaporation until it freezes. (The overflow pipe should turn down into the cistern water so that air cannot pass through the pipe.)

My Toilet Silent Fill Valve Parts

Once the cistern lid has been removed the Toilet Silent Fill Valve is accessible on the left of my cistern. Here you can see the parts labelled:

Pic. 2. The silent Fill Valve and Float System with labels.

Here is the Silent Fill Valve Parts List:

- Arm,

- Clamping Nut,

- Flexible Flat Anti-syphon Tube,

- Float,

- Float Adjustment Screw,

- Input Pipe,

- Output Tube,

- Pinhole Cone & Stopper,

- Pivot,

- Top Cover,

- Water Level Mark.

Adjusting A Toilet Silent Fill Valve Float

When I found water overflowing I removed my cistern lid to access my Toilet Silent Fill Valve’s float. I adjusted the float level so that the cistern water level didn’t rise so high.

The adjustment is made by turning the long screw which has a hexagonal nut moulded onto it. Although it’s shaped like a nut it doesn’t require a spanner to turn it, fingers are sufficient. See the image below where the Toilet Silent Fill Valve Top Cover and Arm have been removed to give a better view of it.

Pic. 3. Here the Clamping Nut, Top Cover and Arm have been removed.

The float is being held up by hand to show the adjusting screw. The knob on the top of the screw attaches to the Arm.

Adjusting My Cistern’s Water Level

To raise the water level: I turn the screw clockwise when looking down on it, i.e. screw it into the float.

NOTE: There is a ❝Stop❞ moulded onto the screw thread (see Pic. 3) to prevent the screw being screwed too far into the float.

To lower the water level: I turn the screw anticlockwise when looking down on it, i.e. screw it out of the float.

NOTE: There is a line marked in the porcelain showing where the water level should be when the cistern is full. Make sure the top of the overflow is above the line by at least 1 cm. But make sure it is well below the screw holes (or any other holes) in the cistern.

Flushing The Cistern With The Lid Off

The cistern can be flushed with the lid removed by poking something suitable through the holes in the Height Adjustable Securing Plate and using it to push the flushing buttons down. Either a button with spindle attached or a screwdriver can be used. Where space permits the buttons can be pressed directly with a finger or thumb. For more information refer to: ‘Dual Flush Toilet Cistern Lid Removal’.

Turning Off My Cistern’s Water Supply

When adjustment of the float failed to stop my cistern overflowing I presumed there must be a problem with the Toilet Silent Fill valve itself, probably the rubber diaphragm within the Toilet Silent Fill Valve. I decided to examine the rubber diaphragm by taking it out of the plastic body. That required me to turn off the cold water supply to the cistern. I have an inline stop tap installed as part of the flexible hose linking the copper supply pipe, where it exits the wall, to the Toilet Silent Fill Valve Support Tube protruding from the bottom of the cistern. So I just had to rotate the tap with a flat blade screwdriver until the slot was across the pipe instead of inline with it. See images below:

Pic. 4a. Water Turned ON

Pic. 4b. Water Turned OFF

NOTE: This type of tap can turn both ways and through 360° but some (like mine) only turn back and forth through 90°.

Repairing My Toilet Silent Fill Valve

Removing The Top Cover

I began by unscrewing the Clamping Nut in an anticlockwise direction. This holds down the Top Cover of the Toilet Silent Fill Valve and seals it against the outer edge of the Rubber Diaphragm.

NOTE: There is a detent protruding from the top of the output pipe which engages the Clamping Nut. I had to force it out of the way of the ridges on the nut so that the nut could be turned.

Then I removed the Top Cover to reveal the Rubber Diaphragm inside:

Pic. 5. Fill Valve with the Top Cover removed and the Diaphragm in place.

NOTE: The Top Cover retaining the Clamping Nut can be removed without disconnecting the linkage from the Toilet Silent Fill Valve operating lever to the float. The whole assembly can then be moved aside by pivoting it on the float adjusting screw (not shown in this view).

Removing The Fill Valve Diaphragm

The Rubber Diaphragm then has to be winkled out revealing the innards below:

Pic. 6. Fill Valve with the Top Cover removed and the Diaphragm removed.

At first I couldn’t see much wrong with the diaphragm but on closer inspection, when I stretched it, I found several splits in the rubber.

Here the diaphragm is pinned, in the stretched position, to a block of wood covered in white paper to display it:

Pic. 7. A Damaged Diaphragm – holes show when it is stretched.

“Why do the rubber diaphragms tear?”

T K Mukasa

Every time the diaphragm goes up and down the area that tears is bent, straightened and stretched. Eventually the molecules rip apart at a place in the material where they are overworked.

The real question is: “How many times should you be able to bend, straighten and stretch this material before the damage is done?” I suspect if it were to be used on a device taking a long space journey it would be able to do it millions of times but it would cost a small fortune.

What have we here? A twopenny-halfpenny device, so it only lasts a few years. Perhaps a better design or a better material that isn’t prohibitively expensive might make it last longer.

“. . . I found your site, looked at the diaphragm and quickly spotted the tear. 10 minutes later and £1.57 later problem solved.”

Richard King

Replacing Fill Valve Diaphragms In General

There has been debate comparing diaphragms with red pins to those with white pins. The questions have been:

- Are they identical?

- Will the white one work in the same fill valve as a red one and visa versa?

Well I’ve got my hands on a white pin diaphragm at last. So I have compared it with a red pin one. I took edge on photos of both and measured their thicknesses and diameters. You can see them side by side in the picture below:

Pic. 8. White and Red Pinned Diaphragms side by side.

The answer to Q1 above is: They are different. Although they are the same diameter, 31 mm, they are different shapes.

The answer to Q2 above is: Because they are the same diameter they can be placed in each others’ fill valves.

So I have tried a white pin diaphragm in my fill valve which should have a red pin diaphragm in it. It did work after I had adjusted the Float Adjusting Screw considerably. I had to screw it out of the float by about 3 cm.

The white pin diaphragm has to travel 2 mm more to close than the red pin diaphragm. To do this a greater force is required above the diaphragm. This is achieved by closing the pinhole earlier in the fill process when the float is low in the water.

As far as I am aware the white pin diaphragms are for use with the twist lock valves. If there is a failure when substituted for a red pin diaphragm don’t blame me. I still intend to use red pin diaphragms in my older valve which has a screw on retaining nut to hold it in place, if I can get them.

Replacing My Fill Valve Diaphragm

I couldn’t get a replacement diaphragm from Wickes in 2014, but I did get one from B&Q.

Other suppliers are:

Pic. 9. Diaphragm

“. . . I then found an own Plumbsure brand replacement at B&Q which works perfectly. Part No. WB540QV3 diaphragm washer for quiet fill valve.”

Mike Robinson

I had to replace my diaphragm again in February 2019. This type was what I had already got as a spare.

Here is the diaphragm held in its operating attitude with the little red Restricting Pin pulled down by gravity. It doesn’t drop out of the hole because the other end of the pin is squashed flat making it too wide to pass through the hole. Make sure the pin can move up and down freely under gravity while submerged:

Pic. 10. The Diaphragm in detail.

The diaphragm is flexible so that the section which shuts off the main flow of water, when filling the cistern, can go up and down relative to the area which seals against the inside of the Silent Fill Valve Tube.

NOTE: Some ask which way up the diaphragm should be. Well the side with the red pin head should face towards the incoming water supply.

Cleaning & Servicing The Parts

Before I reassembled the Toilet Silent Fill Valve I cleaned various parts. It’s quite easy to disconnect the adjustable float screw from the valve operating lever. The lever has a slotted hole and the plastic is flexible so it can be stretched to go over the ball on top of the Float Adjustment Screw. Only after disconnecting the lever from the float can the inside of the valve top be inspected. Below you can see the Top Cover Assembly:

Pic. 11. Top Cover Assembly with the Arm threaded through the Clamping Nut.

Calcium can be removed from all the parts with the help of a descaling agent and the aid of an old toothbrush and a penknife to scrape with. It’s important not to damage the plastic around the pinhole in the Top Cover or the valve won’t function correctly (it may leak). See image below with Clamping Nut detached:

Pic. 12. Top Cover Assembly with the Clamping Nut detached.

Pic. 13. Valve with the Arm removed and the pinhole exposed.

With care I prised the supports on the Top Cover sideways to release the fulcrum pivots of the arm so it could be removed. I was concerned that the supports might break under force. The supports are shaped so that the arm pivots can be clicked into place easily. (I suspect the manufacturer only expected it to be assembled once.)

The Pinhole Cone & The Rubber Stopper

Below is the valve with the arm removed. You can see the underside of the arm with the Rubber Stopper insert in the Top Cover below:

Pic. 14. The Arm (upside down).

NOTE: The rubber Stopper may need replacing if the dimple in it becomes too deep. The dimple’s made when it presses down, over a long time, on the proud Pinhole Cone on the Top Cover. I presumed, incorrectly, that the Stopper was a simple rubber cylinder. I expected it could be removed and turned end over end to present a new flat surface with no dimple. However I have been informed by a reader (Tom Fenwick-Brown) that the Stopper is pressed onto a spindle to hold it. This means it has a hole in the opposite end preventing that type of repair. I have not had occasion to remove my Stopper and look at the hidden end. I suppose the dimple in the stopper could merge with the hole embedded in it from behind. Then it would leak water and not seal the pinhole cone.

“Just one tiny (but important) point regarding your suggestion to: – remove the ‘stopper’ in the arm and turn over to present a new flat surface. This is not possible as the stopper is hollow and sits on a spindle, so the bottom side is open. I was unable to find a replacement anywhere, so I improvised with a shim under the stopper to raise the level and sort the problem. I tried a few tiny rubber washers first but found them too thick, [so] I ended up using a cut out from an old pair of thin rubber gloves, which worked a treat.”

Tom Fenwick-Brown

Reassembling The Toilet Silent Fill Valve

As is often the case reassembly of the parts was the reverse of the dismantling process thus:

- I began by clicking the Arm into the forks of the Top Cover. Then I threading the Clamping Nut over the Arm until it fitted around the Top Cover.

- Next I seated the new Diaphragm in the top of the Inlet Valve body fitting the Top Cover over it.

NOTE: There is a spigot on the edge of the Top Cover. It can be positioned into one of three recesses on the valve body. The spigot will prevent the Top Cover rotating while the Clamping Nut is tightened. The spigot should be engaged with a recess according to the position of the float.

- I Held down the Top Cover by screwing down the Clamping Nut in a clockwise direction.

- Then I pushed the ball on the end of the Float Adjusting Screw into the slot at the end of the Arm.

- All I had to do then was turn on the water supply and adjust the Float.

Flow Restrictors & Filters

A Toilet Silent Fill Valve may have a flow restrictor. It prevents the cistern filling too fast when the water pressure is high. It may also have a filter to stop grit going into the finer parts of the valve.

A restrictor effectively narrows the fill pipe and resists the flow of water. Allowing the cistern to fill too quickly can adversely affect other appliances attached to the water supply. They can suffer from a lack of pressure when the cistern takes all the water. Showers, for example, require pressure to be maintained for them to work correctly.

Restrictors are not usually required if a cistern is fed from a header tank only one or two floors above. The pressure from such a tank will be low enough.

Many a Toilet Silent Fill Valve is supplied with the appropriate restrictor. The plumber decides whether to insert it or not. Some have a low pressure insert to put in its place if the restrictor is not required. What and where it is inserted depends on the design of the Toilet Silent Fill Valve.

An Inlet Filter Problem

Below there is a quote taken from a comment to this post by someone who resolved a filter problem. They had a Toilet Silent Fill Valve slightly different to mine.

“. . . I then remembered, before replacing the diaphragm, that underneath it – in my float arm cap – there’s a filter unit. Shaped like a small bullet – I’d pulled this out to flush it through as the instructions for the float arm, which I have, said to do periodically.

Anyway, I finally realised I’d not pushed this filter unit back properly into the recess under the diaphragm. Thus the diaphragm couldn’t even begin to do its job as it wasn’t being pushed down onto the valve as the cistern filled up! I pushed it firmly in and voila – the waterfall stopped!

So just in case others also have this little filter unit underneath their diaphragm – ensure you push it firmly back into the recess before replacing the diaphragm. Use a pair of long nosed pliers to twist the filter one quarter turn clockwise once it’s firmly pushed in place. The filter has little lugs on it which you can grip with the pliers.”

Marianne Wilford

My Silent Fill Valve Has Been Superseded

My Toilet Silent Fill Valve seems to have been superseded by a new one. It has a Twist-lock cover instead of a screw cover for one thing.

The new one has 18 supports for the diaphragm to rest on. See below where the supports have impressed ridges in a red pin diaphragm:

Pic. 15. The underside of the Top Cover of the new Twist Lock valve with a Red Pin diaphragm.

NOTE: The diaphragm should not be shaped to fit against the 18 supports like it is in this picture. Maybe it should have a white pin and thus be shallower. See Pic. 8.

I now (June 2020) think a red pin diaphragm is not the correct one to use and that the ridges seen in it should not be there.

A Video of A White Pin Diaphragm Being Replaced In A Twist-lock Fill Valve

As far as I can see the top is removed by an anticlockwise quarter turn twist to gain access to the diaphragm. Take a good look at the My Toilet Spares video below showing the diaphragm being replaced:

I have noted that the plumber is not replacing the diaphragm with one with 18 ridges already embedded in it. Also it has a white pin.

I believe the ridges get pressed into the diaphragm if it has a red pin, because it’s the correct diameter but the wrong shape (too deep).

I now know that diaphragms with white pins have different dimensions to those with red pins. However they do have the same diameter. See Pic 8 above.

Reference

1. How A Toilet Silent Fill Valve Works

Go to my reference article in the Reference Library entitled ‘How A Toilet Silent Fill Valve Works’ to see the detail in an addendum to this post.

2. Encyclopedia of Toilets

Check out this Encyclopedia of Toilets. Part of InspectAPedia.

Footnotes

1. How water could syphon back into the supply pipes and be a danger

If the street stop cock or the main house stop tap is turned off then, if the cold tap downstairs in a house is turned on water will come out of that tap when an upstairs tap is turned on (letting air in), or if water from an upstairs cistern can syphon backwards out through a valve which is not held shut. That upstairs cistern water isn’t guaranteed to be clean and once in the cold water pipework it could be drunk. It could have been in the cistern for a long time if the toilet was not regularly used.

Leave a Reply