Post Description

How I renewed the coupling kit which joins my toilet cistern and pan. I did this to repair a Close Coupled Toilet leaking fresh water between the cistern and pan. Water was leaking from the coupling joint when the toilet was flushed.

Introduction

The first sign of a problem was the water on the floor around the base of the closet pan. There was not a lot and fortunately it was clear and without a smell. I cleaned it up but it kept reappearing.

The Signs of Leaking Water

The Paths Taken By The Leaking Water

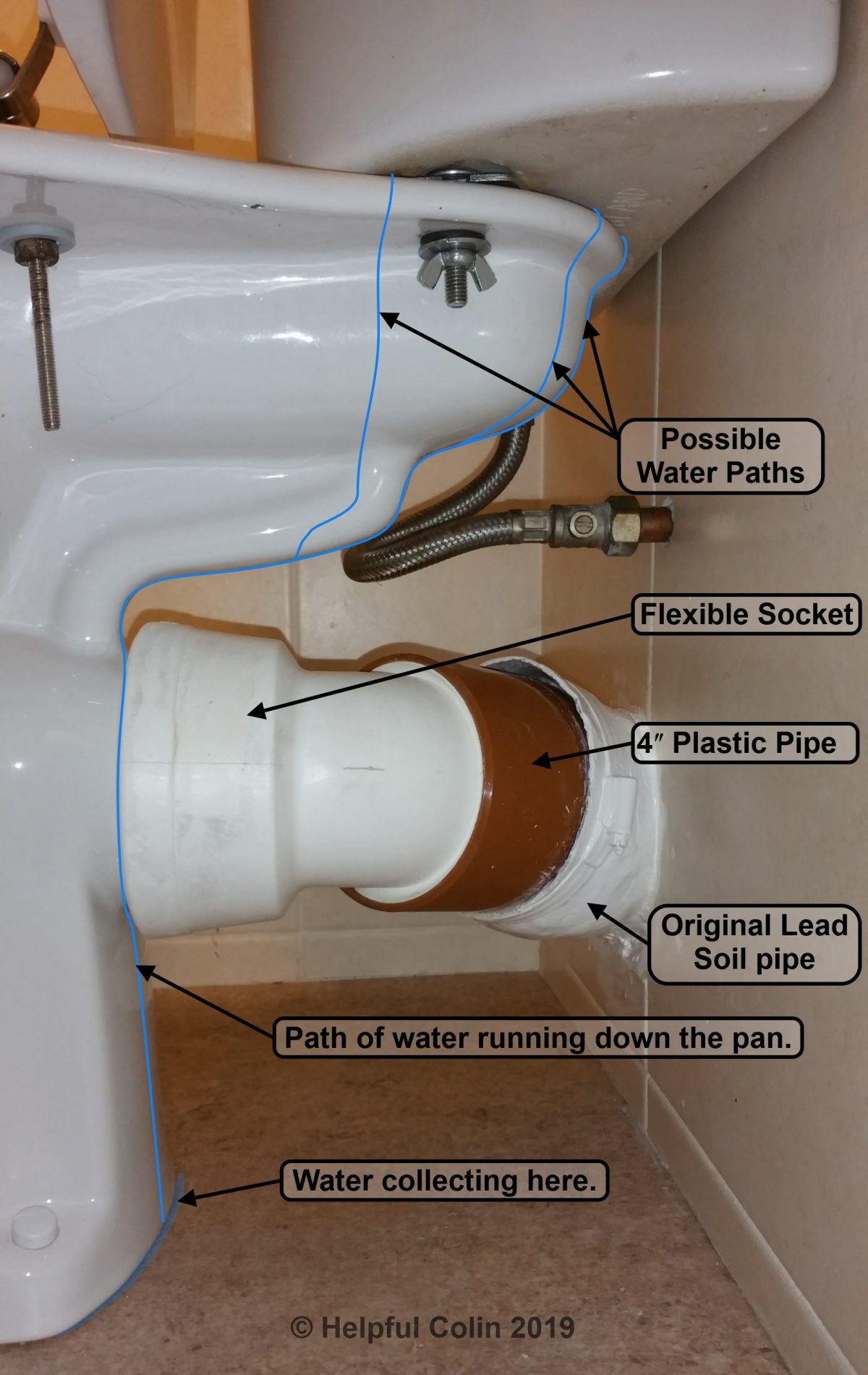

Pic. 1. This Shows Possible Paths For The Leaking Water

On closer inspection it had run down from the top of the pan near its coupling with the cistern. This is difficult to discover. It requires something akin to a headstand with a torch to see it. Another way to detect it can be to feel for wetness on various parts of the closet pan.

NOTE: The leaking water often runs around the toilet outlet giving the impression that it is a sewage leak when its not.

Why Was My Toilet Leaking Fresh Water?

I have had past experience of my toilet leaking water from the coupling between the cistern and closet pan. In this case I guessed correctly that a leaky coupling was the source of the water. How did I guess: well the toilet has been in place since at least 2007, that’s 12 years. I can’t remember if I’ve already changed the coupling on this toilet in those 12 years but I certainly did on the previous one installed in the mid 1980s. That suggests 10 to 12 years is as long as they last when the plate can rust away.

In the past, and in this case, the coupling plate was corroded and the sealing doughnut had lost all flexibility. Under these conditions the seal is lost between the two. The rusty plate can lose its strength if it completely rots away or it can just become permeable. This means water can seep through the rust. Further to that any movement between the cistern and pan isn’t filled by expansion of the doughnut under its own compliance. You can see what remains of my old coupling plate and doughnut in Pic. 2 below.

Pic. 2. The Old Coupling Plate & Doughnut Seal

Pic. 3 (below) shows how the doughnut sits with the coupling plate. This is the orientation seen from underneath the cistern when looking up.

Pic. 3. Old Coupling Plate & Doughnut Seal Together

New Coupling Methods May Never Leak

Modern close coupled toilets often have two holes in the cistern for fitting stainless steel bolts with rubber washers. These are tightened to the cistern to prevent them leaking. In between these bolts is the hole for fitting the outlet valve. When fitted it’s nut is covered with a spongy rubber gasket.

Then when the cistern is lowered onto the closet pan the bolts pass through the anchoring holes and the valve passes into a central hole in the pan. When the bolts are anchored to it with nuts steel washers and rubber washers the rubber gasket is squashed to seal the central hole. The rubber gasket plays the same part as the doughnut in older toilet models. These newer toilets have the benefit of not requiring a metal plate and so don’t suffer from it corroding.

Old Coupling Methods May Leak Eventually

The older method of coupling a cistern directly to a closet pan without a pipe in between uses a steel coupling plate up to 3mm thick. Some thinner ones are pressed into a stronger shape (see other brands and models of toilet). With luck, any new plate will be made of stainless steel or plastic.

Older plates were made of rust-able steel. They may have been painted, pressed from tin-plate, electroplated or galvanised but they rusted nonetheless.

The older plates were certainly not up to the job. Why? Well, during winter months they get bathed in condensation running down cisterns in bathrooms with high humidity levels. The water runs to the lowest point of the cistern which is where the coupling plate is attached. Also toilets are cleaned with corrosive chemicals. These too run down the cistern and along the top of the closet pan so they collect at the inaccessible coupling plate and corrode it.

Not only does the coupling plate get extremely wet but the bolts and wingnuts do too. They can get so rusted that they become difficult to undo when it’s time to effect a repair. The solution is to grease them well during installation.

Unfortunately grease is messy. People get it on themselves when they clean. Children may get it on themselves. It can attract other dirt and hair.

Combined, the condensation and corrosive liquids make a meal of coupling plates. Sometimes rust flakes come out from under the cistern when the toilet is being cleaned. Let this be a warning sign.

When the plate in contact with the doughnut seal rusts it becomes porous and flushing water begins to leak. This leakage isn’t noticeable at first since the condensation is the greater source of water, but it too attacks the plate and worsens the leak.

You may ask why flushing water would come out of the place at which the cistern and closet pan are coupled, since the water pours down and is aimed through the hole in the pan. Well the water is forced down into a confined space with considerable momentum and that is turned into pressure. It then splashes up into the doughnut seal area and escapes any way it can through any gaps it finds.

What Makes A Toilet Unpleasant

From the issues I’ve mentioned in the previous section you can see that toilets are heading off in a dirty direction from day one. None of this is due to their basic purpose but because of design and materials used.

Under the closet pan are all those screw threads and wing nuts hanging down. Some are inclined to go rusty and so may be greased. None of it ideal territory for cleanliness.

Don’t forget how difficult it can be to clean underneath the cistern and between it and the wall too. That’s a good place for hairs and fluff to collect over many years.

Yes this is what silicon sealant is for. Then you hit the problems when it has to be removed for maintenance. Actually I haven’t seen a cistern sealed to a wall. Be aware condensation on the outside of the cistern may get trapped there. Perhaps it’s better for air to circulate.

Where air is damp and still, mould will live.

Replacing The Coupling Plate On A Toilet Leaking Fresh Water

To replace the coupling plate of a close coupled toilet:

- Turn the water supply off and flush the toilet;

- Disconnect the inlet valve from the water supply;

- Remove the cistern lid for access;

- Remove the cistern from the closet pan;

- Remove the outlet valve from the cistern (it secures the coupling plate) and discard the old coupling plate and doughnut seal;

- Clean everything;

- Reassemble the cistern outlet valve using a new coupling plate;

- Re-attach the cistern to the closet pan using a new doughnut seal;

- Re-attach the cistern to the wall;

- Re-connect the water supply;

- Turn the water supply on;

- Replace the cistern lid.

NOTE: Most of these instructions also apply to toilet cisterns using siphons and handles too, not just those with two button outlet valves.

The complete process for changing the coupling plate is detailed in the following numbered sections as per the above list.

1. Turn The Water Supply Off

If the plumbing is up to date the Fill Valve of the cistern will be connected via a flexible connector with a built in Stop Tap. See Pic. 4 below.

Pic. 4. Inline Fill Pipe Stop Tap

If that’s the case just turn the Stop Tap 90° to turn off the water.

If there is no local Stop Tap the main Stop Cock for the property will have to be turned off while the work is done. That will cut off water to all devices not served by a header tank.

2. Disconnect The Inlet Valve From The Supply

After the water supply is turned off flush the toilet with the large flush to empty the cistern. Then unscrew the clamping nut from the Fill Valve. See Pic.5 below. Have an old towel to hand to mop up a small amount of water. This will come out of the connecting hose.

Pic. 5. The Inlet Valve Connection

The cistern is then ready to be removed. It may contain a small amount of water. This won’t spill as long as the cistern is kept upright and the outlet valve/siphon remains in place.

3. Removing The Cistern Lid For Access

The cistern is fixed to the wall with two screws so for that reason alone the lid must be removed. Having the lid off also makes the cistern much lighter to lift off the closet pan once the bolts holding it down have been undone.

A full set of instructions, with pictures, explaining how I removed my cistern lid is available here:

4. Removing The Cistern From The Closet Pan

Fixing The Cistern To The Wall

Cisterns generally have two holes in the porcelain at the back so that they can be screwed to the wall. My cistern is like that so I removed those screws at this stage. Those screws should be made of brass so that they don’t corrode away. Mine weren’t and one corroded but the other didn’t. They both had screw caps but obviously that wasn’t sufficient to protect them.

Pic. 6. Plated Steel Screws Used To Hang The Cistern

Fixing The Cistern To The Closet Pan

The bolts which pull down the coupling plate, and hence the cistern, onto the Closet Pan commonly have Wing Nuts. But they may have hexagonal nuts instead. There should also be steel washers and sometimes there may be rubber washers too. They even the pressure on the closet pan when the bolts are at a slight angle. See Pic. 7 below.

Pic. 7. The Bolts holding The Leaking Toilet Cistern To The Closet Pan

NOTE: When making a repair keep the rubber washers for re-use. The repair kit may not have any.

Loosening The Wing Nuts or Hexagonal Nuts

If not rusted, wing nuts may be loosened by hand. A leather glove may be needed. Either wing nuts or hexagonal nuts can be undone with an adjustable wrench or gas pliers. You have to use whatever tool fits into the available space. It can be hard to see whats happening. The ability to work blind may be required when the toilet is in the corner of a room say.

5. Removing The Outlet Valve From The Leaking Toilet Cistern

When the cistern is lifted off the closet pan it may be dirty. The best place for working on it might be outside. Turn it upside down to drain any water out of it and place it on something soft to protect the porcelain. If it’s a dry day place it direct on a lawn, otherwise use some corrugated cardboard or an old towel on a concrete area.

With the cistern upside down remove the doughnut seal to gain access to the clamping nut of the outlet valve. That nut needs to be carefully removed (anti-clockwise) and re-used. So, one has to be careful not to chew it up with whatever wrench or pliers are used.

The problem is, finding a tool capable of opening to such a large diameter. I used a specialist wrench in the form of Water Pump Pliers with “dinosaur” teeth. Not too good for the plastic but they opened up wide enough to nearly 70mm (2¾”). See Pic. 8 below.

Pic. 8. I Undid The Leaking Toilet Outlet Valve Nut with Water Pump Pliers

The threaded outlet valve outlet tube fits through a 60mm (2⅜”) hole and the clamping nut is about 65mm (2½”) Across the Flats.

The outlet valve has to be held with one hand while the other operates the wrench.

6. Clean Everything

This is the time to clean anything that looks dirty and to check if either the inlet valve or outlet valve need any attention, or replacing.

A rusty coupling plate may have left some nasty looking rust marks on the porcelain of the cistern and closet pan. These may need a fine abrasive to remove them. I use a green scourer as shown below in Pic. 9.

Pic. 9. Green Fibre Scouring Pad

If the sealing ring is removed make sure it is either replaced or bedded back down on a clean and smooth area of the cistern and the valve.

Pic. 10. The Outlet Valve

7. Reassembling The Outlet Valve & The New Coupling Plate

If particles of rubber have broken off the old sealing ring then carefully scrape them away from the valve flange and the perimeter of the cistern hole. Then reseal with a new sealing ring.

Fixing the coupling plate is the reverse of dismantling. Thread the outlet valve through the central hole in the cistern from the inside after applying the sealing ring to the screw thread. Put the coupling plate on the outside and then the nut. When tightening the nut it’s important to either have the bolts in place or be sure they can be slotted into place afterwards. With my cistern there are dimples in the porcelain for the bolt heads to fit in and I can put them in place after the coupling plate is fixed.

Pic. 11 below shows the reassembled cistern with the outlet valve clamping the coupling plate to the cistern. Pic. 11a is without the doughnut seal and Pic. 11b shows how the doughnut seal sits against the coupling ring.

Pic. 11. The Cistern With A New Coupling Plate & Seal

Some people like to apply sealing compounds to the seals and rubber rings used to make watertight connections. I find that when parts are new or undamaged there’s no need. Rubber rings are used because they seal well as long as they are seated correctly and have the right amount of pressure applied when tightened.

If there are dents in flanges, chips out of porcelain or damaged seals then some sort of flexible sealing filler may have to be used. The favourite these days seems to be silicon sealant. It can be a nuisance when parts are dismantled again in the future and it all needs scraping off. I like silicon grease because it’s water resistant, inert and remains flexible. It provides lubrication for rubber parts when they are stretched and squashed.

8. Remounting The Toilet Cistern On The Closet Pan

Having re-equipped the cistern with a new coupling plate it can be fixed to the closet pan. First the doughnut seal needs to be laid in the circular recess around the large central hole in the pan. See Pic. 12 below.

Pic. 12. The Closet Pan Holes For The Cistern Fittings

Then, as the cistern is lowered, the bolts have to be aligned to pass through the two holes either side of the central hole in the pan. This is done by jiggling the cistern around until they drop through.

If the cistern doesn’t sit against the wall behind in a neat and tidy fashion, it might be necessary to adjust the position of the coupling plate. The cistern can be lifted off and the coupling plate twisted to a different position without loosening the clamping nut. Then the cistern can be re-positioned on the pan.

To secure the cistern these items must be put on each bolt in the following order:

- a rubber washer,

- a steel washer,

- a wing nut.

The wing nut can be tightened by hand. Wearing a leather glove allows more tightening with less pain. Draw down the cistern by equal amounts on both sides to squash the doughnut seal evenly all around it.

Although pliers or a wrench can be used to tighten the wing nuts, remember the closet pan is made of porcelain and can be damaged. There’s no need to crush the doughnut seal out of existence to stop the water escaping.

9. Holding The Cistern Against The Wall

Pic. 13. The Cistern, Ready For Re-fixing To The Wall

Finally the screws which hold the cistern up against the wall should be re-fitted. These screws should be made of a none corrosive metal. Usually brass screws are used but stainless steel screws are just as good. I have obtained some No. 12 × 2½” brass screws, see Pic. 14 & 15a, from SCREWSLINE to replace my old steel ones. I also managed to cover them with the original Screw Caps, see Pic. 15b, which work as a cushion between screw head and porcelain.

Pic. 14. New Brass Screws To Hold The Cistern To The Wall

Pic. 15. Cistern Hung With Brass Screws & Capped

10. Reconnect The Water Supply

The flexible hose must have a sealing washer inside the clamping nut, then it can be re-attached to the inlet valve. Care must be taken so it doesn’t get cross threaded. It can be screwed on a long way by hand but at the final tightening an adjustable wrench will be required.

Pic. 16. The Inlet Valve Connection

11. Turn The Water Supply On

At this stage the cistern lid is still off but the green and white flushing buttons on the top of the flush valve will be accessible for testing.

The input valve should be checked to make sure the float is working as it should be (lift it up and lower it down.)

Turn the water back on by opening the Stop Tap on the flexible hose, or open the premises Stop Cock. (Whichever turned the water off.)

Test the toilet thus:

- Make sure there are no water leaks on the flexible hose and its connections;

- Make sure water is not leaking around the bottom of the cistern;

- The cistern should fill to the line on the inside of the cistern;

- Adjust the float as required;

- The cistern should not overflow into the overflow pipe unless the water level goes above the line in the cistern.

- If the cistern fills to the line and stops and doesn’t overflow, press the float down and let it fill some more until it overflows;

- Check that the overflow setting is at a safe height;

- Check that the small flush works;

- Check that the large flush works.

12. Replace The Cistern Lid & User Buttons

A full set of instructions, with pictures, explaining how to replace my cistern lid is available here:

Leave a Reply