Introduction

There are three mains safety issues regarding extension cables and 13 amp plugs covered in this post which are:

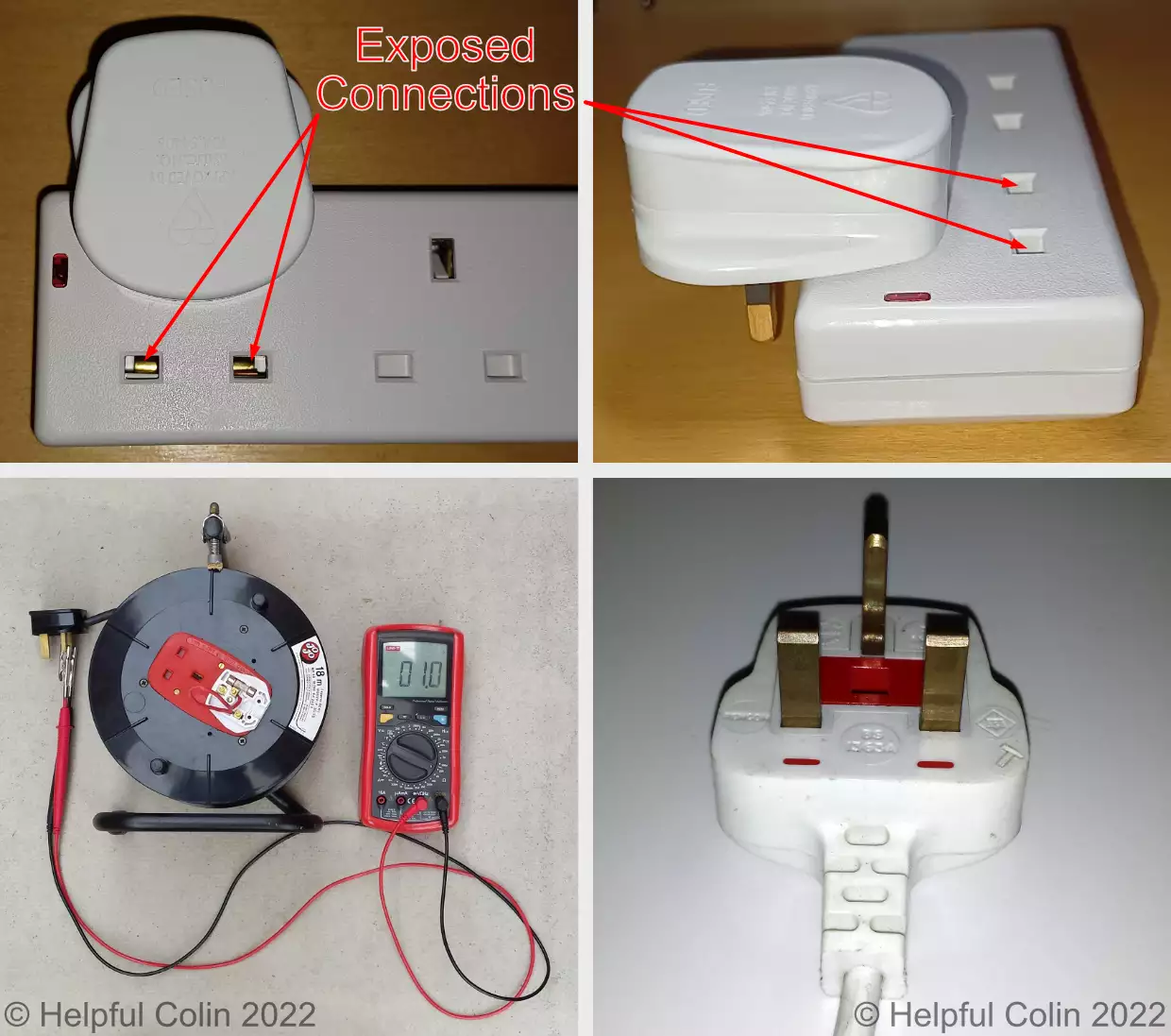

- UK 13 amp plugs have mains safety issues where sockets can become dangerously exposed. I came across it by chance when I landed on the PlugSafe site. I’ve linked to their site in this post so you can see what they have to say about the subject. I’ve also produced my own pictures depicting the problem so you can see what I’m referring to. Full credit to PlugSafe for making us all aware.

- A fire risk due to overheating of coiled up mains extension cables when used for heavy loads.

- A risk of shock when using old 13A plugs which don’t have insulated pins for Live and Neutral connections.

Mains Safety Issues Due To Loophole in BS 1363 – Credit to PlugSafe

There is a problem in BS (British Standard) 1363. It has a mains safety issues in the form of a loophole in the regulations which allows manufacturing of extension sockets with the earth pin socket too close to the edge. When it is too close to the edge the plug can be plugged into the socket in an inverted fashion exposing the LIVE and NEUTRAL pin’s sockets.

Most multi-way portable socket outlets allow this insertion of the EARTH pin into the EARTH pin socket. Doing so opens the shutters of the sockets for the other two pins – LIVE and NEUTRAL. People can then poke metallic objects such as pins, paper clips and small keys and screwdrivers into the open holes and get a severe electric shock. This is a clear danger visible in my photos below:

Note: It is important to ensure that children are not allowed unsupervised access to this type of extension.

It is to be hoped that this oversight will eventually be corrected with a revision of BS 1363.

You can visit PlugSafe’s website at BS 1363 Plugs and Sockets (fatallyflawed.org.uk) to get their view on this. The subject is mentioned at the bottom of the page under ‘Loophole in BS 1363’.

Further Mains Safety Issues With Mains Extension Cables

After publishing the original post, which just covered the previous issue, I received a couple of comments from Alastair Wilson. You can read Alastair’s comments at the end of this post. He reminded me of two other mains safety issues regarding 13 Amp Mains Extension Cables and 13 Amp Plugs. They are:

- The fire risk when using extension cables, which are still coiled up, are carrying a heavy current.

- The danger to persons (particularly children) if they use old 13 Amp Plugs without the insulation on the Live and Neutral pins that later plugs have.

Read on for further explanations.

1. Using A Coiled-up Mains Extension Cable Can Be Dangerous

The wire in a mains extension lead has some resistance even though it is very low. Electricity flowing through any resistance generates heat, so heat is dissipated in extension cables when in use.

The equation used to calculate the power dissipated in an extension cable is:

PC = (IC)2 RC

Where:

- PC = Power dissipated in the cable in Watts,

- IC = Current in Amps drawn by the appliance connected to the cable,

- RC = The Loop Resistance1 in Ohms of the Live & Neutral wires in the cable.

An Example of A Mains Extension Cable

In this example I will work out the power dissipated in an 18m long extension cable capable of carrying a current of 13A. This mains extension cable can be used to supply a 3kW electric heater if used to its maximum capacity. See the picture below:

Measuring An Extension Cable’s Loop Resistance

The following measurements were made using the schematic diagram in Fig. 1 below:

Checking The Test Lead Resistance

First I measured the resistance of the test leads of my ohmmeter because it can be significant when compared to the low value of resistance found in a good electrical conductor such as wire in a cable. To do this I had to:

- turn the ohmmeter on and set it to the lowest range,

- connect the test lead probes together with their crocodile clips.

See the picture below:

As you can see, from the ohmmeter screen above and Fig. 1, the sum of the resistance of the two test leads was:

0.05Ω + 0.05Ω = 0.1Ω.

Measuring The Total Loop Resistance

Secondly I shorted the Live and Neutral wires together at the socket end of the cable. I did this by inserting an open mains plug into the socket with its Live and Neutral terminals connected by a thick piece of wire.

I then connected the crocodile clips on the ohmmeter test leads to the live and neutral pins of the mains plug at the other end of the cable (I made sure they weren’t touching each other). As you can see, from the ohmmeter screen below and Fig. 1, the loop resistance of the test leads plus the cable was 1Ω.

Calculating The Extension Cable Loop Resistance

Using the formulae:

RC = R2 – R1

Where:

- R1 = Resistance of the test leads,

- R2 = Combined resistance of test leads and cable,

- RC = Loop resistance of the cable on the reel.

I subtracted the resistance of the test leads from the loop resistance of the cable and test lead combination thus:

RC = 1 – 0.1

This gave a cable loop resistance of:

RC = 0.9Ω

Calculating The Power Dissipated In The Cable When Used At Full Capacity of 13 Amps

Putting values in the equation for the power dissipated in an extension cable gives:

PC = (13)2 × 0.9 = 152.1W

Where:

- PC = Power dissipated in the cable in Watts,

- IC = 13 Amps,

- RC = 0.9Ω.

Using The Mains Extension Cable At Full Capacity

The power dissipated by this example extension cable at full capacity is:

152.1 Watts.

It’s 18m long so the power per metre is:

152.1W ÷ 18m = 8.45W/m (Watts per metre).

I will give this some sort of meaning:

A person’s hand is about 10cm wide. So grabbing a handful of cable (a tenth of a metre) will let a person feel the heat. They will feel 0.845W of heat which, I can assure you, is nothing. They won’t notice that it’s above ambient temperature.

I conclude that uncoiling a cable in the open air alleviates heat dissipation problems. So that’s how we should use them – uncoiled.

The power must dissipate within a small volume when the cable is coiled up tightly onto a reel. The surface of the coil does have the air around it but deeper into the coil there will be no circulating air and plenty of plastic insulation. The insulation is both an electrical insulator and a heat insulator. So the inner core just gets hotter and hotter.

Unlike metals PVC insulation melts at relatively low temperatures. Soft PVC allows tensions on the conductors to make them cut through the insulation and short out or start sparking. This can result in fire. The circuit breaker or fuse may cut the power off but the damage to the cable will be permanent.

Using The Mains Extension Cable At Less Than Full Capacity

Mostly extension cables are used at less than full capacity so they don’t get anywhere near as hot as I have indicated they might at full capacity.

Note: There is a square law involved so if the current is halved the power dissipated will only be a quarter of the maximum at 38.025W.

Consequently it is possible to use an extension cable coiled up if a low power is required by the connected appliance and if it is only required for short periods. So using it to supply an electric heater might be dangerous but to extend an electric light may be O.K.

NOTE: The only advice I can safely give is to:

- uncoil an extension cable under all circumstances before use to prevent it overheating,

- ensure coils of wire on the ground don’t become trip hazards by using the shortest extension cable that will do the job.

2. Using Old Mains Plugs Without Insulated Pins Is Dangerous

The Danger Involved

When inserting or removing a 13 Amp mains plug fingers can wrap themselves around a plug and touch the pins. This can happen to anyone who finds them tough to extract from the socket. Children and the aged with their weak grip are particularly susceptible. These people can potentially get a lethal electric shock by doing this.

It doesn’t matter if fingers touch the earth pin since it makes contact with the earth connection in the socket before any other pin. (That’s why it’s longer.) Consequently the earth pin is always safe.

If someone’s fingers touch the live or neutral pins after the live pin makes contact in the socket they will get a serious electric shock.

The Danger In Detail:

- If the neutral pin connects before the live pin it should be safe since neutral is at earth potential.

- If the live pin connects before the neutral then the neutral pin will also become live and dangerous if the appliance is switched on, or has no switch. The neutral pin will no longer be live when the plug is pushed home and it connects.

New & Old Style BS1363 Mains 13 Amp Plugs

New Style Plugs

Since 1984 insulated Live and Neutral pins has been a requirement of BS1363 – 13A plugs, thus removing the danger.

See this article in Wikipedia.

Old Style Plugs With Mains Safety Issues

The danger comes from continued use of old style plugs made before 1984 which have uninsulated pins. Anyone using them should have them replaced.

I have to confess I have found some on items I have inherited or assembled before that date. They look like this:

I also found I had several Multiplug adapters in a drawer which were below standard. I’ve dismantled them and put the brass in my scrap brass collection and binned the plastic parts.

Footnotes

- Loop Resistance is measured by joining two wires of a cable together at one end (to make a loop), and measuring the resistance between the wires at the other end with an ohmmeter (or Wheatstone bridge). This method measures the resistance of the two wires added together because they are in series.

END OF POST

Leave a Reply