Introduction

Tin Whiskers are a crystalline growth made of the element tin. They are in the form of a very thin straight hair with one end attached to the tin from which they are formed.

They often form on lead free solder used to fix components to circuit boards now that lead is banned.

The Tin Whiskers I Found

In my case they have grown on a piece of tin plated steel used to screen electronic components which are part of a central heating wireless thermostat radio receiver. This receiver has developed an intermittent problem and doesn’t switch on my central heating when it should.

I suspect a tin whisker growing inside the component screening can is the cause of the electrical fault, and over time it grew large enough to touch some electrical connection and make a short circuit.

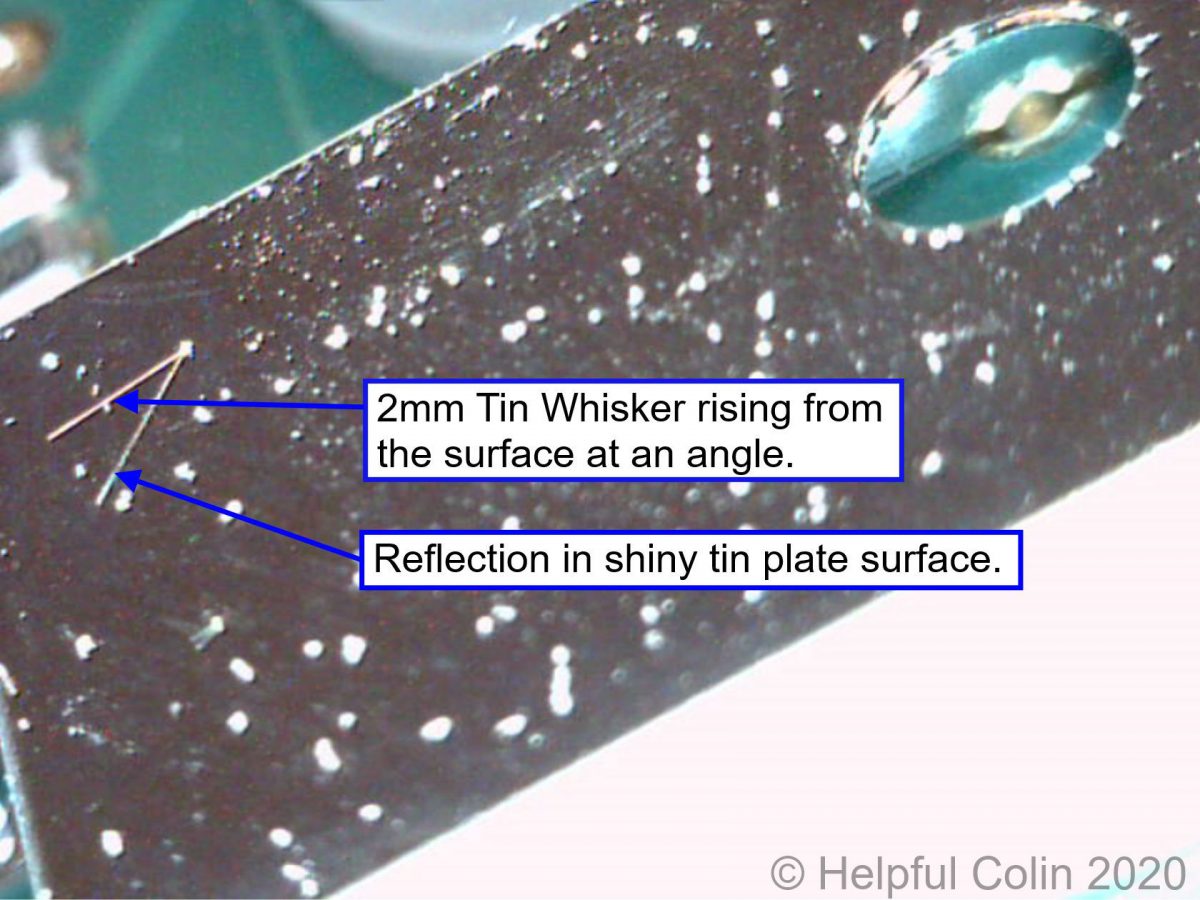

Since I have not completely dismantled the item to find out for sure I don’t know if that is correct. However as you can see from the pictures below, the Tin Whiskers that I have found on the outside of the screening can are up to 2mm long. Although I already knew of their existence these are the first I have seen in 50 years of handling electrical or electronic devices.

I have used a USB microscope connected to my computer to photograph them, but I have had a lot of difficulty. They are so thin they are hardly visible with a watchmakers eyeglass with 10x magnification.

The tin plate shown here is covered in minor scratches which I think has opened the surface to their formation. There are many small but visible stumps along these scratches which seem to be the beginning of whiskers. See below:

Leave a Reply